HOME >

Steel/Aluminum Products >

HOT ROLLED STEEL

HOT ROLLED STEEL

Business Contacts:Michael Chen/Extension:33265/Email:[email protected]

Chung Hong Hot Roll Mill

Chung Hung’s Hot Rolling Mill was completed in less than two years sinceMay. 22nd, 1995. First hot rolling band was produced from HSM on Apr.28th, 1997.

We set a new record for the shortest construction time of similar plants in the steel industry.

Hot Rolled Mill and Skin Pass Line produce all kinds of hot rolled bands and hot rolled temper grade coils with excellent quality and with the thickness of 1.2~12.7mm and 1.2~6.0mm, respectively. Width of 900~1560 mm.

Chung Hung Steel has been accredited several international certificates including ISO9001, ISO 14001 and OHSAS 18001 in 2002 and hot rolled coils produced widely applied for producing hardware, containers, automobile bodies, home appliances, structural pipes, as well as construction pipes in addition to producing cold rolled coils and galvanized materials.

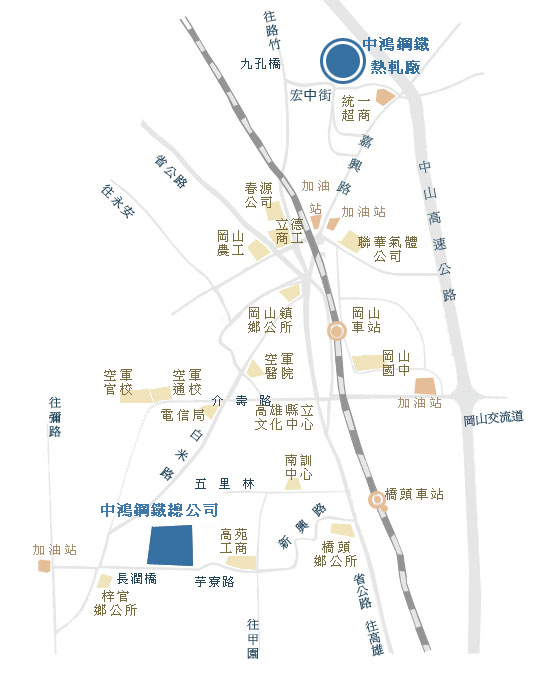

Location Of Hot Rolled Mill

Hot Rolled Product Brief

Hot rolled coils, also known as black skin coils, can be suitable for re-rolling, slitting, and piping.They have a wide range of applications. The annual design production capacity of Chung Hung’s hot rolled mill is 2.4 million metric tons, which may produce hot rolled bands and hot rolled tempered coils conforming to all kinds of specifications with the thickness of 1.2~12.7mm and width of 900~1560 mm.Hot rolled products are made from slabs which are reheated in the hot strip mill at proper temperature, rolled in the roughing mill, through the coil box, rolled in the finishing mill, cooled in the laminar flow cooling system, and eventually down coiled into hot rolled bands in the down coil. The hot bands will be conveyed to the skin pass mill for pertinently tempering, crop shearing, weighing, packaging and marking to be further processed into tempered coils. All hot rolled products of Chung Hung have been accredited with ISO 9001 for quality management system certificate, ISO 14001 for management system certificate, and OHSAS 18001 for occupational health and safety management system certificate.

Hot rolled coils have the characteristics that include adequate strength, well toughness, good weld ability, and easy formability, which can be used not only as the main materials in producing cold rolled coils, but also widely applied for hardware, automobile body plates, home appliances, structural pipes, construction pipes, and construction steels for structure. Specifications and main applications of hot rolled products are listed in the following table:

Production Flow

Reheating Furnace

Roughing Mill

1. High pressure scale breaker at entrance and exit to increase

thesurface quality of products.

2. Continuous reversing 4 high rolling mill with screw down

and balance oil cylinder mechanism for rolling stability.

3. Equipped with edger and AWC width auto control system

for more precise rolling width than the tradition fashion .

4. Semi-auto work roller change equipment for reducing roller changing time so as to increase the production capacity.

5. Auto lubrication system for the transmit equipment to

reduce maintenance time so as to increase the utilization

of the equipment.

Coil Box

1. Saving total space of the hot rolling production lines and

the costs of establishing equipments.

2. Keeping the coil temperature uniform and reducing cold

mark through coiling.

3. Roughing mill and finishing mill can work at the same

time to reduce pacing time.

4. Optimum Cutting Control System to reduce cutting loss

of crop so as to increase the output rate.

Finishing Mill

mechanisms for more feasibility in production scheduling and stability of crown of coils.

3. Use AGC Auto thickness and shape control system to

control the thickness of steel strips more precisely and

secure the thickness required by customers.

4. Available thickness of 1.2~12.7mm (the manufacturing

process of 18mm having been independently

developed).

5. Automatically rapid work rolls change equipment adopted so as to reduce the time of changing rollers.

Laminar Flow Cooling System

promptly fix the temperature deviation.

and the side spray system is equipped in each region.

Down Coil

jumping control of three wrapper rolls for achieving the

down coiling function.

marking control system.

Skin Pass Mill

coils.

General Product Specification

Size Code | Use | |

API | 5L | Line Pipe / Casing Pipe |

A36 | Carbon structural steel | |

ASTM | A1011 | Forming/Structure Quality/High Strength Low Alloy |

JIS | G3101 | Rolled steels for general structure |

G3125 | Superior atmospheric corrosion resisting steels for welded structure | |

G3131 | Hot rolled mild steel plates, sheets, and strip | |

G3132 | Hot rolled carbon steel strip for pipes and tubes | |

G3193 | Dimensions, mass and permissible variations of hot rolled steel plates, sheets and strip | |

G4051 | Carbon steels for machine structural use | |

G4304 | Hot rolled stainless steel plates, sheets, and strip | |

SAE | J403 | Carbon steels |

CH | HF | Checked sheets and strip |